|

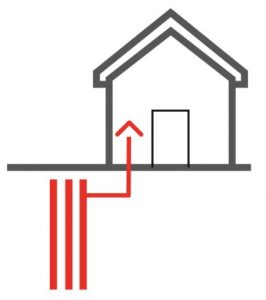

Ground

(ground collector or geothermal probe)

More >>

|

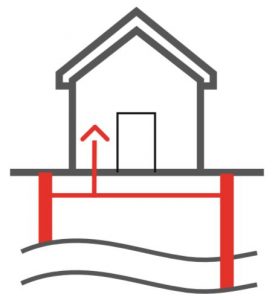

Water

(groundwater)

More >>

|

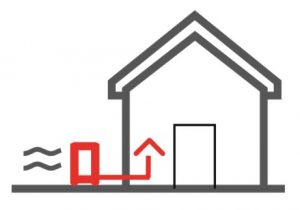

Air

More >>

|

| Temperature throughout the year |

Fairly constant between 0°C and 9°C. |

Constant between 9°C and 13°C. |

Highly variable from -20°C to +40°C. |

| Efficiency |

Typically achieved COP ranges from 4—5. |

Typically achieved COP ranges from 4.5—6. |

Depends on the quality of the heat pump. COP of European manufacturers ranges from 3—5 (low-cost heat pumps 1.5—3.5). |

| Availability |

Everywhere; for geothermal probes, water protection areas or underground caves (karst) may be an obstacle. Availability and quality do not change over time. |

In some places; where quality groundwater is available and it is not a water protection area. Quality and water level may change over time. |

Everywhere; less common in very cold climates. Availability and quality do not change over time. |

| Installation |

Simple; can be done independently (ground collector).

Complex; requires a qualified drilling contractor (geothermal probe).

Usually, the contractor completes the heat source installation, meaning they bring the connection pipes into the building and finish the groundworks. The planning and execution must be carefully prepared. |

The suction and discharge well are installed by a specialized drilling contractor using appropriate equipment. Typically, the contractor provides a turnkey heat source, bringing pipes and cables from the wells into the building and completing the earthworks. |

Simple; can be done independently with a proper base and connection to the boiler room.

Complex; carried out by a contractor as a turnkey solution. |

| Installation duration |

1—3 days |

1—2 days |

1—2 days |

| Required permits |

Mining permit for geothermal probe (provided by the contractor). |

Water permit and mining permit for wells deeper than 30m (provided or assisted by the contractor). |

No special permits required. Must comply with noise regulations. |

| Investment cost |

Medium for a ground collector, high for a geothermal probe. |

Medium |

Low |

| Subsidy |

High

(final investment cost is similar to that of an air-to-water heat pump) |

High

(final investment cost is similar to that of an air-to-water heat pump) |

Low |

| Common mistakes and issues |

Incorrectly sized geothermal probe or collector for heat source use;

Lower thermal output from the ground. |

Poorly constructed suction or discharge well – water contains too much sand, suction well does not drain properly;

Shallow wells (1—4m) may cause very low water temperatures when snow melts;

Failure to follow recommendations for installing balancing valves, water filters, pressure gauges, and the PIL module. |

Incorrect placement, obstructed air intake or exhaust, improper location, causing noise for neighbors or sleeping areas.

Incorrectly sized heat pump power for demand and climate conditions. |

| Thermal output |

For 1 kW heating power, 30—35 m of ground collector or 15—18 m of geothermal probe is required. |

For 1 kW heating power, a groundwater flow of 0.23 m³/h is required. |

/ |