Was embarking on the path of entrepreneurship merely a result of losing your job, or had you been toying with the idea of starting your own business before?

By the time I turned fifty, with 25 years of work at Gorenje in the field of refrigeration technology and renewable energy sources, I never even dreamed of going on my own, as it was often associated with entrepreneurship back then. The decision to start my own business was largely influenced by my wife Cvetka. She said, ‘You better go on your own because you have enough knowledge and experience. You can start in my father’s “blacksmith” workshop in part of the economic building. You can paint the components of new machines on the “bars” of the nearby hayrack and plum tree. The warehouse will be in a hundred-year-old wooden house, and you can have your office in our house close to me. I’ll manage the books, prepare lunches, and clean.’

How were the beginnings?

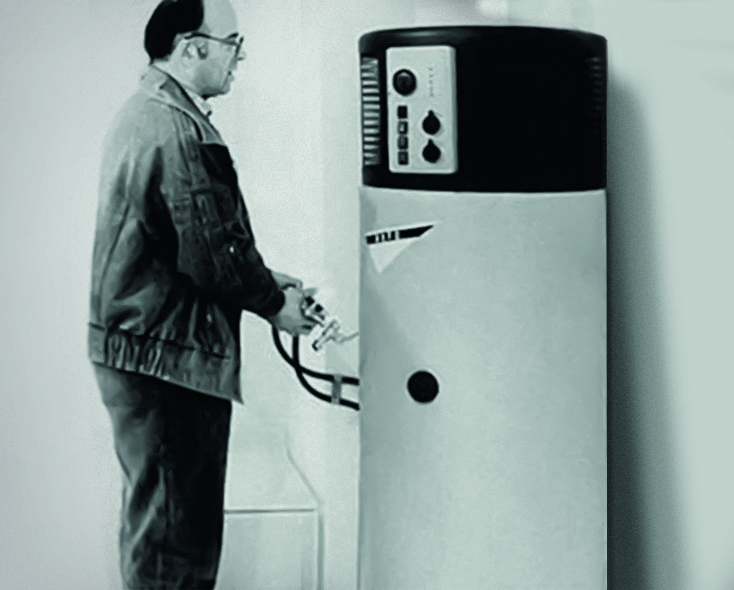

It took just over two years for (then) Termo-tehnika to become recognizable for heat pumps for sanitary water and basement cooling devices. The demand for products quickly increased. Fortunately, my in-laws began to slowly abandon agricultural activities. We quickly adapted the agricultural spaces and hired additional workers. By the beginning of the new millennium, there were almost a dozen of us. We were suffocating in work, especially when we started appearing at fairs in Celje and Gornja Radgona.

Every beginning is difficult, and probably not everything went according to plan for you either…

In the nineties, it was difficult to get, for example, compressors or gas. My wife and I often went to Austria, bought there, and then paid expensive customs duties. The significant difference between the “initial” and today’s company was diminishing, the products were becoming better, with a nice design and high quality. The working method was still campaign-like. We often extended the workday and worked voluntarily and self-initiatively sometimes even on weekends because we were all very excited about the success and eager to work. Due to constant disruptions in production, as a result of too broad a program, we also did not manage to optimize the production process, so the management quickly decided to abandon some more artisanal tasks and increasingly focus on serial production, especially heat pumps.

“Heating heat pumps enabled an unforeseen further development of the company. In 2007, this development was crowned with the title of Zasavje-Savinja Gazelle. This was a somewhat unexpected recognition for a company with a very short lifespan but rapid development in all areas. At that time, there were barely twenty employees.”

You built the company during a time of uncertainty, political changes, and the absence of advertising and sales as we know them today. How did you ensure visibility and sales in the nineties?

We mostly presented heat pumps in a few larger shopping centers. Often, together with a colleague who lectured on solar collectors. Occasionally, due to competing devices, there were even heated debates among the audience, about what is better, collectors or heat pumps. Sales mostly took place through word of mouth, and later we also started attending fairs.

Those times were certainly different, and there were probably many similar anecdotes?

Indeed. For example, we had to build a suitably large trailer for a Renault R19 car for transportation. Towards the end of its lifespan, loaded with three people and 500 kilograms of cargo, it could no longer overcome the slopes in the hilly terrain of the Slovenian Hills. Often, two colleagues had to get out for a few hundred meters, and it even happened that we had to unload the heavier cargo from the trailer.

The year 2015 marked the relocation to larger premises, just a stone’s throw from the first location of the company. How did it all go?

In 2011, we found ourselves in a spatial predicament for the third time. There were already about forty employees. We decided to find a new plot in the emerging industrial zone of the municipality of Braslovče in the village of Trnava near the Šentrupert highway exit. At that time, a special story about state-municipal opposition to entrepreneurship development in Slovenia began. Personally, as a procurator, I dealt with all kinds of bureaucracy from the municipality of Braslovče to government ministries for three years to get permission for new construction in the already reserved area. In 2015, we managed to build a modern business-production facility with an area of more than 5,000 m2 with the potential to employ up to 130 workers. We fought for this location mainly because it is in the immediate vicinity of the old workshop and our homes. Another significant advantage is its location in the middle of the Savinja Valley (Slovenia), at the intersection of the Ljubljana – Maribor highway and the planned connection to the third development axis towards Carinthia and Lower Carniola.

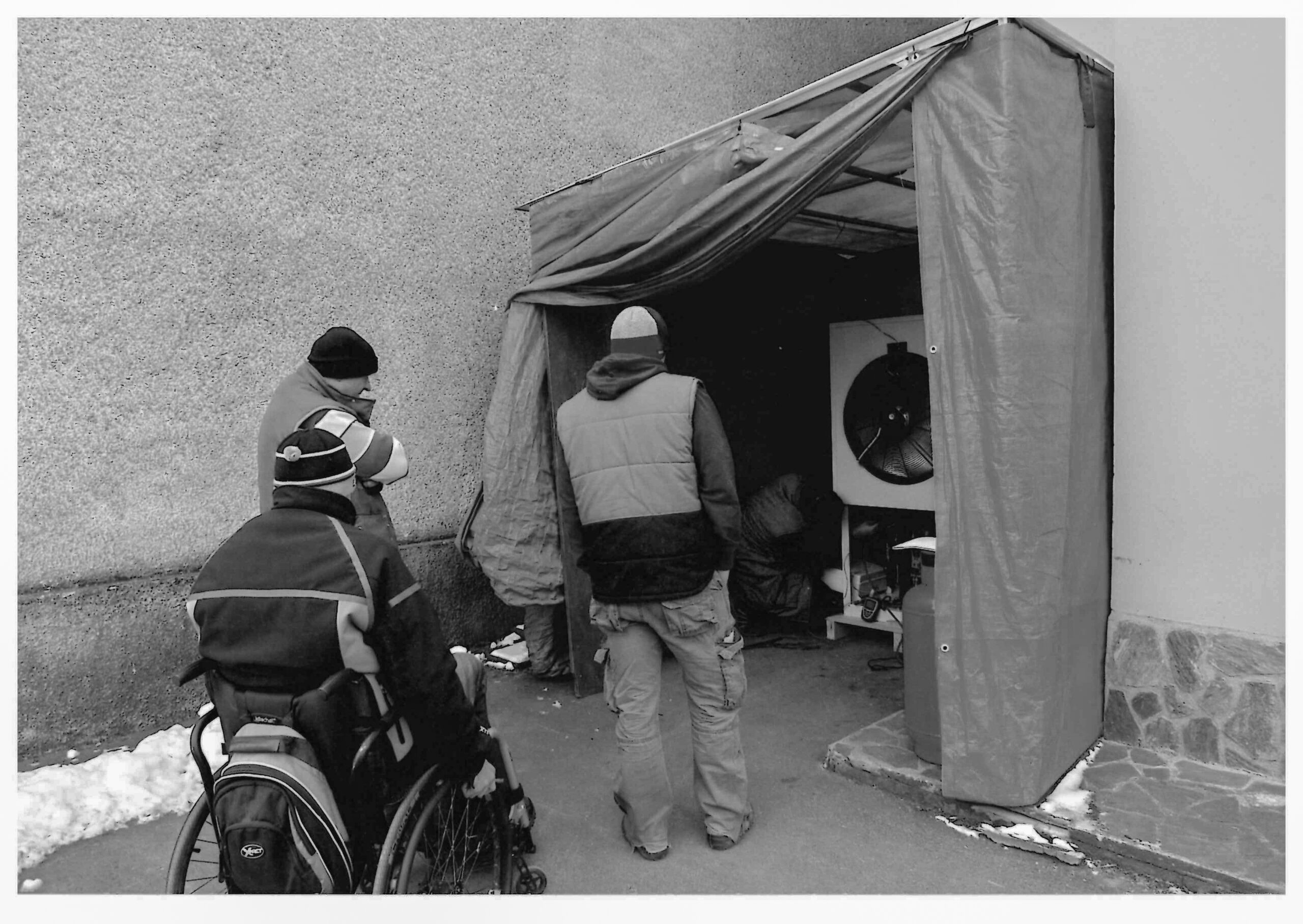

In the new building, there is a large modern laboratory for development and precise measurements of device performance, even in the most demanding weather conditions. How did you conduct measurements before when there was no laboratory?

Outside the company’s main building at the time, we set up an improvised tent to make it easier to capture the climatic conditions for measurements. The modular laboratory had insulated walls and was equipped with air conditioning, making measurements easier, and the quality of measurements was already reliable. This was a significant step towards easier development work, which has always been our guiding point.

What do you consider the biggest difference between the beginning of the company’s operation and now, when the company has grown in all aspects?

The shortest and probably correct answer would be almost everything. Absolutely, there is a huge difference in everything except perhaps the knowledge, which was more than enough for the needs at that time.

“Regarding the difference between the company from thirty years ago and today, I can illustrate it with a ‘railway comparison.’ Back then, we traveled in worn-out freight cars on winding tracks with a coal-powered locomotive. Today, after thirty years, we are racing in modern, even double-decker, large train compositions on a fairly straight double-track route with electric power.”

Today, the company collaborates with several, mainly Slovenian, component suppliers, as production is mass-scale, and it wouldn’t be feasible to manufacture all components. How did you secure certain components in the early days?

We prepared the frames ourselves and bent the sheet metal. I hung sheet metal ends and pipes on branches in the meadow, first washed them, and then sprayed them with spray paint in white, gray, or any color, sometimes feeling dizzy from all those fumes. And that paint somehow miraculously endured (laughter).

You were one of the main initiators for granting subsidies for the purchase of heat pumps, similar to those we know today and are granted by the Eko Fund…

Mostly, it was a pioneering period of development, expansion, use, and subsidization of devices and systems in already independent Slovenia. At that time, I also met several Slovenian experts in this field. My colleagues from the Faculty of Mechanical Engineering in Ljubljana, the late Professor Dr. Peter Novak, once my mentor, and still active Professor Dr. Alojz Poredoš, a leading Slovenian expert in refrigeration technology, were particularly helpful. Despite some opponents, all these efforts still yielded satisfactory results. We have a good system to promote the use of renewable energy sources, which, in my opinion, is very comparable to other EU countries.

We know that the idea and the product alone are not enough for the success of a company. What qualities are needed to lead a successful company?

In the first place, you must have some qualities such as perseverance, diligence, flexibility, courage, appropriate interpersonal relationships, and of course, the necessary knowledge. We must not forget some initial capital, and a bit of luck is also welcome. It seems that I also had a bit of that. Similarly, I can now claim that for the successors, who surpass me in most of the listed qualities.

When you mentioned successors… You retired from the company about five years ago, and your son Bogdan took over your work. KRONOTERM is synonymous with a family business, and over the years, the extended family has been involved in the work. What can you say about the current management of the company?

Generally speaking, and judging by the results, I can say that my wife and I have good successors. Son Bogdan, as the director, and his wife Nives can handle sometimes incredible workloads, especially considering their care for a family with three young children. Son-in-law Dr. Dean Besednjak, as the assistant director and head of the customer service department, is occupied with the company all day long, with our daughter Nataša, a mathematics professor at the Secondary School Center in Celje and co-owner of the company, supporting him. My niece Alenka, who has been working as an accountant in the company for more than twenty years, completes the leading trio. All these former colleagues of mine would deserve the name Holy Trinity in the Christian world.

The company is celebrating its 30th anniversary this year. What thoughts inspire you on such an important anniversary?

The transition from a craft operating mode to such a large company as it is today required the introduction of numerous processes and the development of precise strategies. This path was certainly not easy, and it demanded a considerable amount of time and changes in the mindset of colleagues. Working in such a pleasant environment has become pure joy, crowned with even faster company development. If we continue like this, ten years after moving in, we will employ the planned 130 employees and produce 50 million heat pumps. This means that we are already facing the fourth spatial constraint.

What are you most proud of?

I am proud of the entire company management because they lead the company successfully, fairly, responsibly, and honestly. The company is committed to audits, and every year it concludes with an unqualified opinion. Thanks to Director Bogdan and his assistant Dean, as well as the entire team, for the gazelle successes over all these years. Our achievements enrich Slovenia, and beautiful and highly efficient products delight customers and contribute to the well-being of our wonderful planet Earth. My wife Cvetka and I are very proud that the seeds planted thirty years ago have enabled all of us to reap a very beautiful and rich harvest.

For more information about KRONOTERM heat pumps, please contact us HERE.